USG

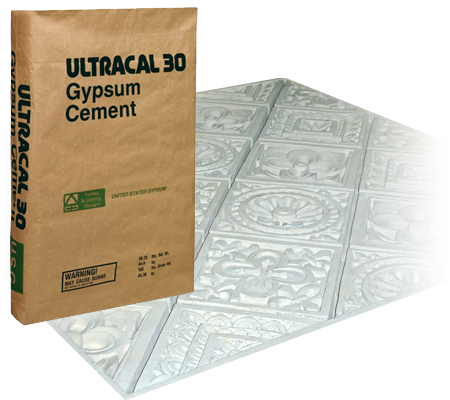

Ultracal® 30

Ultracal® 30

12 in stock

Couldn't load pickup availability

AVAILABLE IN 5, 25, AND 50LB OPTIONS IN THE DROPDOWN

USG Ultracal® Brand 30 Gypsum Cement is designed for the patternmaking industry as the

ultimate gypsum cement tooling medium. When extreme accuracy and greater surface hardness

are required (as in duplicator models), use USG Ultracal 30 Gypsum Cement. It provides extremely

low expansion properties, gradual set and a long period of plasticity.

Ideal for splash-casting molds and models for phenolic, polyester and epoxy resins, USG Ultracal 30

Gypsum Cement is water soluble – there is no need for organic solvents for cleanup. USG Ultracal

30 Gypsum Cement is noncombustible. When properly used, USG Ultracal 30 Gypsum Cement is

easy to work with. Always follow handling and use directions and safety warnings on the package.

MIXING INSTRUCTIONS

Use potable water at temperatures between 70 °F (21 °C) and 100 °F (38 °C). Because variations

in slurry (USG Ultracal 30 Gypsum Cement and water mixture) temperature produce variations in

set time, it is important to keep both the USG Ultracal 30 Gypsum Cement and water in a stable

temperature environment prior to use. The higher the temperature of the slurry, the shorter the set

time. Conversely, the lower the temperature of the slurry, the longer the set time.

Weigh both the USG Ultracal 30 Gypsum Cement and the water prior to use for each mix. The

water-to-USG Ultracal 30 Gypsum Cement ratio is critical because it governs the strength and the

density of the final cast.

Sift or strew USG Ultracal 30 Gypsum Cement into the water slowly and evenly. Do not drop large

amounts of USG Ultracal 30 Gypsum Cement directly into the water as proper soaking of the

USG Ultracal 30 Gypsum Cement may not occur. USG Ultracal 30 Gypsum Cement should be fully

dispersed in the water prior to mixing. Small batches require less soaking time than large batches.

See USG IG503 Plaster Mixing Procedures for specific soaking instructions.

Mixing USG Ultracal 30 Gypsum Cement slurry is one of the most important steps in producing

USG Ultracal 30 Gypsum Cement casts with optimal strength, absorption, hardness and other

important properties.

Mechanically mixed slurries develop uniform casts with optimal strengths. USG Ultracal 30 Gypsum

Cement can be mechanically mixed through both batch and continuous processes. Proper blade

and bucket dimensions are important for obtaining the best batch mix (see USG IG503 Plaster

Mixing Procedures for details).

Longer mixing times result in higher mold strength and shorter set times.

POURING

To prevent air entrainment and provide a uniform, smooth surface, careful pouring of USG

Ultracal 30 Gypsum Cement slurry is necessary. Agitation of the filled mold is a further step used

to prevent air at or near the mold surface. Whenever possible, USG Ultracal 30 Gypsum Cement

slurry should be poured carefully in the deepest area so that the slurry flows evenly across the

surface of the case mold.

Pouring a large amount of slurry directly on the face of the case mold may result in slight

densification of the USG Ultracal 30 Gypsum Cement mold at the point where it strikes the surface

of the case. This produces a hard spot, giving uneven absorption.

DRYING

All casts should be dried as quickly as is safely possible after manufacture so that maximum

physical properties can develop. Dry to a constant weight.

The best drying rooms or ovens provide 1) uniform and rapid circulation (minimum of 15-30 fps

(4.6-9.1 mps)) of air with no “dead spots” having little or no air movement, 2) equal temperatures

throughout the entire area, and 3) provisions for exhausting a portion of the air while replacing

it with fresh air. High humidity surrounding the drying room or oven inhibits drying efficiency

because the air pulled into the room is incapable of picking up much moisture from the molds.

The maximum temperature at which USG Ultracal 30 Gypsum Cement molds are safe from

calcination is 120 °F (49 °C). With substantial free water in the mold, a higher drying temperature

can be used initially without difficulty. As drying progresses, the temperature must be reduced to

prevent calcination. Before removing molds from the dryer, the temperature should approach that

of the area around the dryer to prevent thermal shock.

STORAGE AND USE

When properly used, USG Ultracal 30 Gypsum Cement is easy to work with. Keep indoors at

temperatures between 65 °F - 75 °F (18 °C - 24 °C) and 45% - 55% RH. Do not stack more than

two pallets high. Keep from drafts. Rotate stock. USG Ultracal 30 Gypsum Cement should be used

within 6 months of the manufacturing date located on the package. Always follow handling and

use directions and safety warnings on the package.

Share

- Choosing a selection results in a full page refresh.

- Opens in a new window.