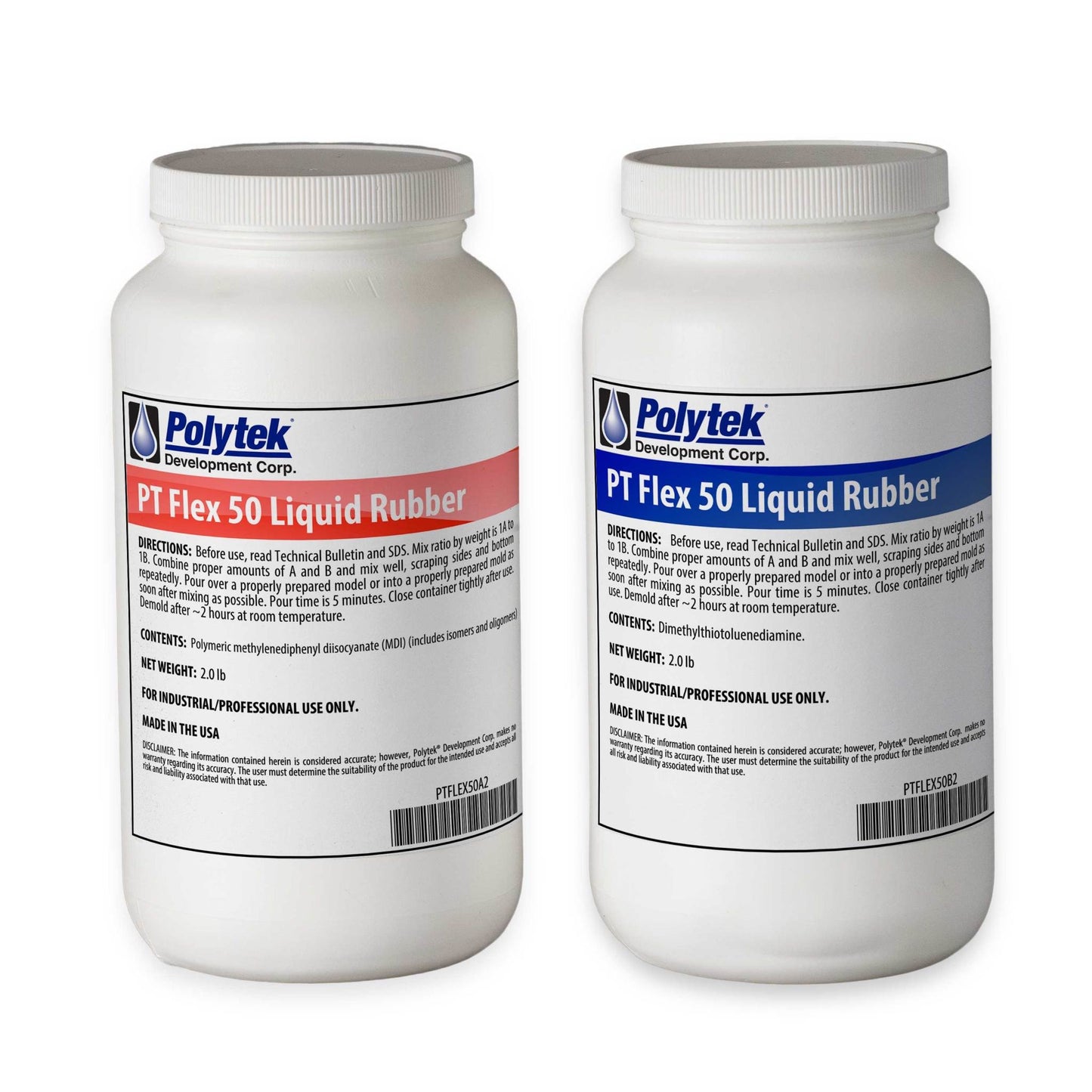

Polytek

PT Flex Series

PT Flex Series

Low stock: 1 left

Couldn't load pickup availability

DESCRIPTION: PT Flex products are two-component, fast-setting polyurethane rubbers that cure at room temperature (RTV). Available in a variety of hardnesses, these products are excellent for prototyping and model making applications and for the casting of production parts, props, tools, and more.

BEFORE USE: Thoroughly read Safety Data Sheets, product labels and the “SAFETY” section in this Technical Bulletin.

MODEL PREPARATION: Porous models, such as wood, plaster, stone, pottery, or masonry must be sealed. Multiple coats of paste wax dried and buffed will seal most surfaces. Potters soap can be used as a sealer for plaster. Lacquer, paint, PVA, and Pol-Ease® 2350 Release Agent also work well as sealers for many surfaces. The properly sealed model should then be coated with a release agent (e.g., Pol-Ease® 2300 Release Agent). Alternatively, PolyCoat, a sealer and semi-permanent release agent, can be used on most porous or non-porous models. Porous models must be vented from beneath to prevent trapped air from forming bubbles in the rubber.

Models made of sulfur-containing modeling clay (e.g., Roma Plastilina) should be sealed with shellac. [CAUTION: When shellac is used as the sealer, it must be thoroughly coated with release agent because

polyurethane rubbers bond tenaciously to shellac.]

Non-porous models (e.g., metals, plasticine, wax, glazed ceramics, fiberglass, and polyurethanes) should be coated with release agent such as Pol-Ease® 2300 Release Agent or PolyCoat.

If there is any question about the compatibility between the liquid rubber and the prepared model surface, perform a test cure on an identical surface to determine that complete curing and good release are obtained.

MIXING AND CURING: Before use, be sure that Parts A and B are at room temperature and that all tools are ready. Surface and air temperatures should be above 60°F during application and for the entire curing period.

Check mix ratio. Shake or stir Part B if directed by the product label. Weigh Part B into a clean metal or plastic mixing container and then weigh the appropriate amount of Part A into the same container. Mix

thoroughly. Hand mixing with a Poly Paddle is best to avoid mixing air into the rubber. While mixing, scrape the sides and bottom several times to ensure thorough mixing. Pour the rubber as soon after mixing as possible for best flow and air bubble release.

Allow rubber to cure at room temperature, 73°F (22.7°C). Carefully demold after the listed “demold time”. Final cure properties are obtained in about seven days. Heat accelerates the cure and low temperatures slow the cure. Avoid curing in areas where the temperature is below 60°F (15°C). Both Parts A and B react with atmospheric moisture and, therefore, should be resealed or used up as soon as possible after opening. Before resealing, PolyPurge, a heavier-than-air, dry gas, can be sprayed into open containers to displace moist air and extend storage life.

SOFTENING THE RUBBER: Add Poly 74/75 Part C Softener to PT Flex products for a lower viscosity mix and a softer cured rubber. When using Part C, cure time is longer and there is some loss of strength in the rubber and increased tendency to shrink after repeated castings. Perform small-scale experiments to determine the best amount of Part C to use.

ACCELERATING THE CURE: Poly 74/75 Part X Accelerator can be added to increase the speed of curing but working time may be reduced dramatically. Heat also accelerates the cure. It is recommended not to

exceed 140°F (60°C). Perform small-scale experiments to determine the best amount of Part X to use.

THICKENING FOR BRUSH-ON: Add PolyFiber II or Fumed Silica to mixed Parts A and B to thicken the liquid mix to a gel for application by brush or trowel.

COLORS: Add PolyColor Dyes to PT Flex Liquid Rubber Part B before mixing with Part A to create unique rubber color. Add up to 0.5% PolyColor Dye of the total mixed weight when using PolyColor Black, Brown, Blue, Green, Red and Yellow. Add up to 2% PolyColor Dye of the total mixed weight when using PolyColor White and Fleshtone.

USING THE MOLD: Typically, no release agent is necessary when casting plaster or wax in PT Flex molds. For casting plaster: sponge, dip or spray the mold with Pol-Ease® Mold Rinse and then pour plaster on the wet mold to reduce air bubbles in the plaster and aid release. For casting resin, first apply Pol-Ease® 2300 Release Agent or PolyCoat Sealer & Release Agent. For casting concrete, use a form release, such as Pol-Ease® 2650 or 2601 Release Agent. Avoid solvent-containing releases since they can cause mold distortion (i.e., shrinkage or swelling).

After repeated casting with certain resins, plaster and concrete, molds may shrink slightly since these materials extract oils from the mold. The proper selection of release agent and/or barrier coat can minimize this effect. If shrinkage becomes evident, a light application of Pol-Ease® Mold Dressing can help to restore the mold to its original dimensions.

PT Flex molds last many years if stored undistorted on a flat, non- porous surface in a cool, dry location out of direct sunlight. If occasional outdoor use is required, add 0.5% UV Additive to the total mix weight to reduce the characteristic surface degradation caused by sunlight. Never store PT Flex molds outside as UV exposure will eventually degrade the rubber.

CLEAN UP: Wipe tools clean before the rubber cures. Denatured ethanol is a good cleaning solvent but is highly flammable and must be handled with caution. Coat work surfaces with wax, Pol-Ease® 2300 Release Agent or PolyCoat so that cured rubber can be easily removed.

SHELF LIFE: For best results, store products in unopened containers at room temperature (60-90°F/15-32°C). Use products within six months from date of shipment. Part B darkens with age, but product performance is not affected.

SAFETY: Before use, thoroughly read Safety Data Sheets and product labels. Follow safety precautions and directions.

Share

- Choosing a selection results in a full page refresh.

- Opens in a new window.