Ransom & Randolph

Primcote® Binder

Primcote® Binder

Low stock: 3 left

Couldn't load pickup availability

High Performance, Industry Leading Binder

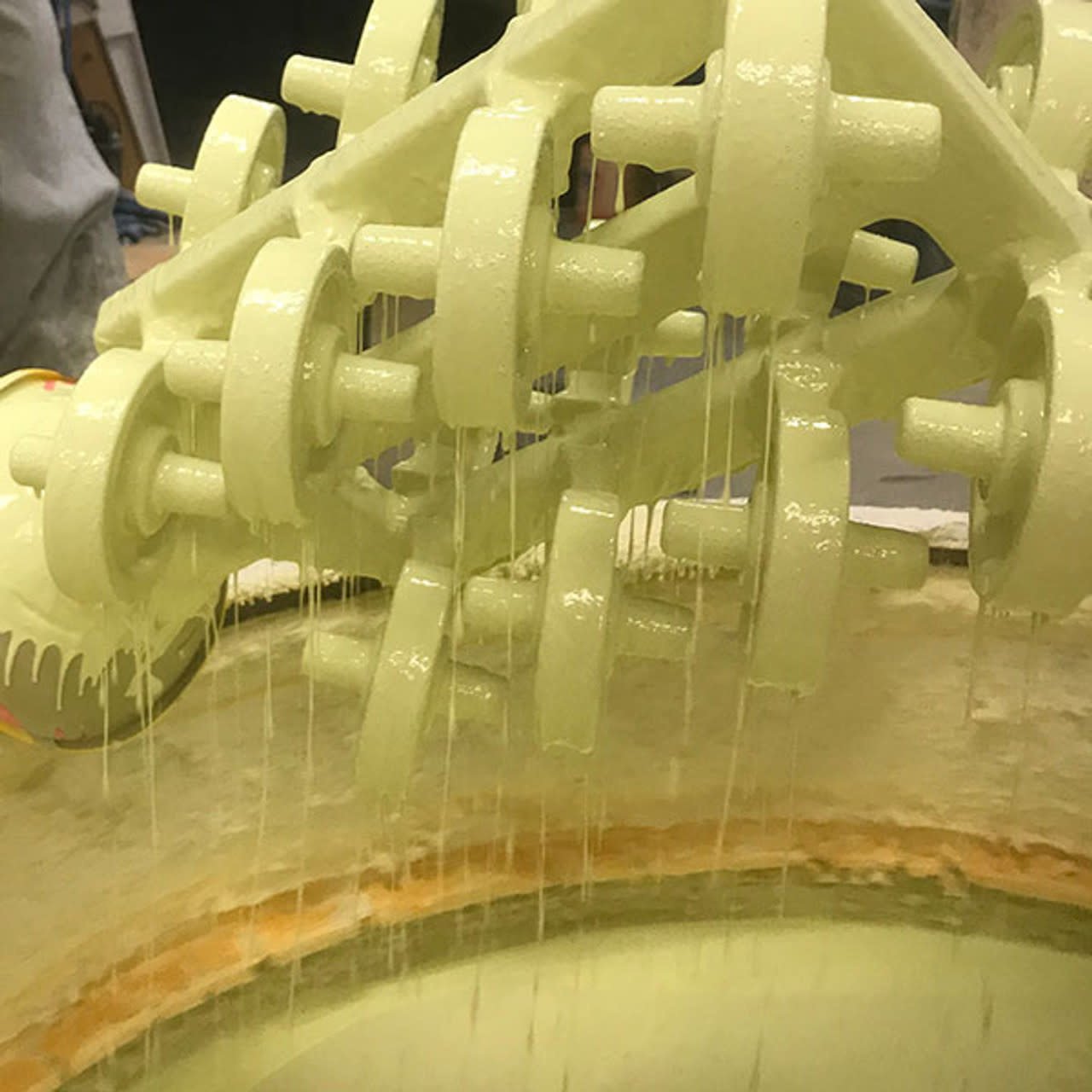

Developed to optimize ceramic shell slurries, Primcote binder is the investment casting industry’s leading colloidal silica based primary binder. Primcote binder was formulated to eliminate buckling, lifting and cracking of primary shell coats.

Primcote binder allows faster drying of primary coats with lower humidity and/or increased air circulation. Shell coats using Primcote binder can not be over dried as shell coats using standard colloidal silica can.

Primcote binder contains a wetting agent, an antifoam agent and a color indicator to monitor shell dryness, as well as several other proprietary ingredients. Primcote binder is compatible with conventional refractory materials and shell room equipment.

Whether casting simple or complicated parts, Primcote binder is the industry’s primary binder of choice.

Typical Material Properties*

|

Base Composition |

Colloidal Silica |

|

Other Composition |

Proprietary |

|

Total Solids Content (Including SiO2) |

30.0%/weight |

|

Particle Size (Approximate) |

10 nm |

|

pH at 77°F (25°C) |

10.6 |

|

Specific Gravity |

1.18 |

|

Weight / Volume |

9.85 lbs/gal (1.18 kg/l) |

|

Na2O Content (Weight) |

0.48% |

|

Particle Charge |

Negative |

|

Color with ReDip™ indicator |

Greenish Yellow |

|

Color without ReDip indicator |

Milky White |

*These results are based on the testing methods, frequency and procedures of Ransom & Randolph or its approved suppliers.

The levels referenced herein are only for general guidance and do not constitute a firm specification.

Formulations

If you currently have a primary slurry formulation, use the same percentages and loadings of your current refractories. The following formulations are for casters just starting out.

|

|

|

|

Formula for 10 Gallons (lbs) |

Formula for 10 Liters (kgs) |

||||

|

Intended Slurry Use |

Target Slurry Density (g/ml) |

Target Viscosity (sec)** |

Primcote binder |

Ranco- Sil™ 4 fused silica |

Zircon (-200 mesh) |

Primcote binder |

Ranco-Sil 4 fused silica |

Zircon (-200 mesh) |

|

Ferrous |

2.99-3.03 |

16.5-18.5 |

43.9 |

— |

206.7 |

5.28 |

— |

24.85 |

|

Non- Ferrous |

1.69-1.73 |

21.8-27.1 |

47.0 |

95.4 |

— |

5.65 |

11.47 |

— |

**Viscosity measured using through the hole method with a #5 Signature Zahn cup.

Application Recommendations

- Remix the Primcote binder prior to use to ensure a homogeneous blend of

- For best results, weigh all ingredients when making up a new slurry or making additions to an existing

- When building the slurry, add the refractory If more than one refractory is used, add the lowest density refractory first: fused silicas (2.2 g/cc), aluminosilicates (2.7 g/cc), zircon (4.5 g/cc). Add refractory slowly for best results.

- New and makeup slurries must be prepared with a propeller mixer, not in a rotating tank. This ensures proper dispersion of the refractory The propeller mixer must be of adequate HP and RPM. Excessive mixing action can introduce air into the slurry and cause erratic viscosity and/or bubbles in the slurry coat.

- As with any slurry, the viscosity of the slurry must be stable before A stable viscosity is one that does not change by more than 1 second when checked at 1 hour intervals. Viscosity can be increased by adding more refractory and decreased by adding more binder.

- It is required to replace water lost to When water is needed (based on test results for viscosity and/or binder solids), use distilled or deionized water as opposed to tap water, which can contain contaminants that can negatively affect slurry life.

- Antifoam, wetting and bactericide agents are already formulated into Primcote binder and other additions may not be compatible. Contact R&R’s technical team before making these additions to the slurry.

- Patterns must be clean and free from silicones or other contaminants before

- It is not usually necessary to use a prewet before applying the first primary coat to the wax If a prewet is needed, use Primcote binder only.

- If a prewet is needed between coats, the Primcote binder should be diluted to 26% binder solids (binder to water ratio of 5.8:1 by volume, 6.9:1 by weight). Drain the prewet well so that no pockets of liquid are left on the pattern.

Slurry Control Procedures

Slurry Control Worksheets are available for download at www.ransom-randolph.com. Slurry Control Worksheets allow you to input data directly and help you calculate values.

Slurry Testing Frequency

R&R recommends running the following tests accordingly.

|

Slurry Test |

Recommended Testing Frequency |

|

Slurry Viscosity |

Two Times Per Shift |

|

Binder Solids |

Two Times Per Week |

|

Binder pH |

Weekly |

Target Binder Solids Range

The target binder solids range for Primcote binder is 28.8-30.8% by weight.

|

Specific Gravity |

Binder Solids |

Specific Gravity |

Binder Solids |

Specific Gravity |

Binder Solids |

|

1.160 |

26.8 |

1.173 |

28.8 |

1.186 |

30.9 |

|

1.161 |

27.0 |

1.174 |

29.0 |

1.187 |

31.0 |

|

1.162 |

27.1 |

1.175 |

29.1 |

1.188 |

31.2 |

|

1.163 |

27.3 |

1.176 |

29.3 |

1.189 |

31.3 |

|

1.164 |

27.4 |

1.177 |

29.5 |

1.190 |

31.5 |

|

1.165 |

27.6 |

1.178 |

29.6 |

1.191 |

31.6 |

|

1.166 |

27.7 |

1.179 |

29.8 |

1.192 |

31.8 |

|

1.167 |

27.9 |

1.180 |

29.9 |

1.193 |

31.9 |

|

1.168 |

28.1 |

1.181 |

30.1 |

1.194 |

32.1 |

|

1.169 |

28.2 |

1.182 |

30.2 |

1.195 |

32.3 |

|

1.170 |

28.4 |

1.183 |

30.4 |

1.196 |

32.4 |

|

1.171 |

28.5 |

1.184 |

30.6 |

1.197 |

32.6 |

|

1.172 |

28.7 |

1.185 |

30.7 |

1.198 |

32.7 |

Safety

OSHA-approved respiratory protection should always be worn to avoid inhalation of respirable silica dust, which can result in an irreversible lung disease, silicosis. Such exposure includes slurry makeup, casting, knockout and cleanup. Refer to SDS for specific details.

Storage & Handling

Keep from freezing. Primcote binder must be maintained above 35°F (2°C) to prevent the material from precipitating irreversibly and making the product unsuitable for use. Binder stored in transparent or translucent containers should be sheltered from direct sunlight. Shelf life is 1 year from date (MMDDYY) in batch lot number on label. Rotate stock to maximize shelf life.

Technical Tips

For additional information and recommendations, refer to the Shell Building, Slurry Control, Autoclaving, FlashFire Dewax Method and Viscosity Cup Correlations Technical Tips available for download at www.ransom-randolph.com.

Slurry Control Worksheet Download

As the conditions or methods of use are beyond our control, we do not assume any responsibility and expressly disclaim any liability for any use of this product. Information contained herein is believed to be true and accurate but all statements or suggestions are made without warranty, expressed or implied, regarding accuracy of the information, the hazards connected with the use of the material or the results to be obtained from the use thereof. Compliance with all applicable federal, state, and local regulations remains the responsibility of the user. All potential liability related to the sale and use of this product is limited to the cost of the particular goods sold in their respective transactions.

Share

- Choosing a selection results in a full page refresh.

- Opens in a new window.