The Compleat Sculptor, Inc

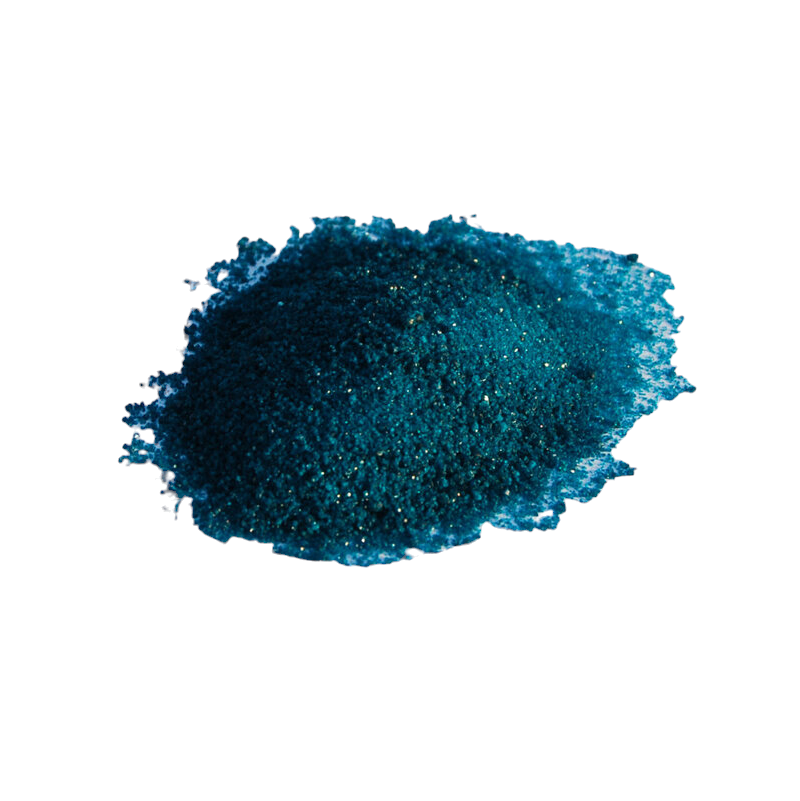

Cupric Acetate (Cu(CO2CH3)2 · H2O) 1lb

Cupric Acetate (Cu(CO2CH3)2 · H2O) 1lb

Out of stock

Couldn't load pickup availability

Blue Green - semi-matt For Bronze and Brass

Cu(CH3COO) 2 - H2O

Ingredients

- Cupric Acetate... 20 gm

- Ammonium Chloride... 35 gm

- Distilled Water... 1 L

Process

Applied liquid.

With mortar and pestle, grind ingredients with a little water. Then add to remaining water. Dab and wipe on sparingly with soft cloth, to leave an evenly moist surface. Allow to dry in air. Repeat procedure once a day for several days as color develops. Dry for several days during which time the patina develops further. When there is no more surface change, wax to finish.

The most important part is to let it dry throughly between applications and up to two weeks before waxing.

Blue Green For Bronze and Brass

Ingredients

- Cupric Sulfate... 20 gm

- Cupric Acetate... 20 gm

- Ammonium Chloride... 10 gm

- Acetic Acid (6% soln.)... to form a paste.

Process

Applied paste - several days.

Using a mortar and pestle, grind ingredients to a creamy paste with the acetic acid. Apply paste to object with a soft brush giving a thick coating. Dry for one day. Wash dry residue away under cold water using a soft brush. Apply a thin layer of paste with a soft cloth and dry again for one day. Wash off residue again. Apply thin layer and dry until good variegated patina is achieved. When treatment completed, dry thoroughly. May be waxed.

Orange-Brown For Bronze and Brass

Ingredients

- Cupric Acetate... 25 gm

- Cupric Sulfate... 19 gm

- Distilled Water... 1L

Process

Heat immersion (15 min)

Immerse in hot solution (176°F, 80°C). Color develops gradually and remove after 15 min. Wash and dry wax finish if choose.

Share

- Choosing a selection results in a full page refresh.

- Opens in a new window.